What is an industrial water filter?

Introduction: Water resources are crucial in industrial production, so industrial water filters are widely used in many fields. The main function of industrial water filters is to remove particles and impurities from water or wastewater, thereby improving water quality and reducing pollution. This article will discuss the functions and types of industrial water filters, their importance in industry, and how to choose a suitable industrial water filter.

What is an industrial water filter?

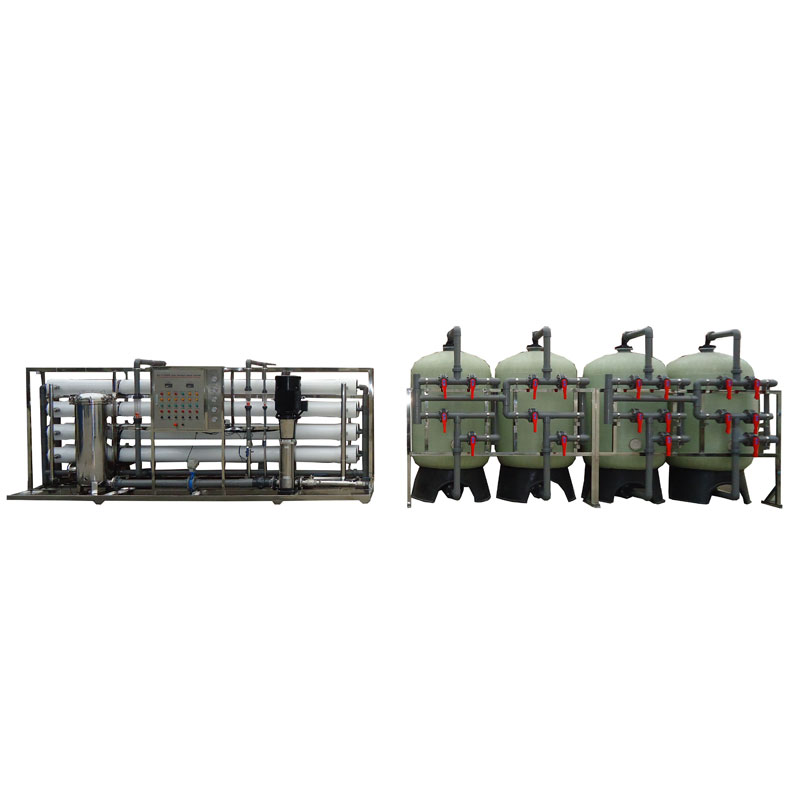

An industrial water filter is a device used to remove particles and suspended solids from water or waste streams. They provide cleaner water by removing contaminants from the water through a variety of filter media and technologies. Common industrial water filter types include sand filters, activated carbon filters, bag filters, reverse osmosis systems, and more. Different types of filters are suitable for different industrial applications and water treatment needs.

Sand filters are typically used to remove larger particles and suspended solids, while activated carbon filters excel at removing organic matter and odors. Bag filters are a convenient and fast filtration method suitable for treating large flows of water or wastewater. Reverse osmosis systems remove most dissolved substances from water, including salts, heavy metals and chemicals, through a semipermeable membrane.

The choice of industrial water filter depends on the nature of the water to be treated and the specific application needs. For example, for applications that require the removal of organic matter and odors, an activated carbon filter may be more appropriate, while for applications that require high-purity water, a reverse osmosis system may be the best choice.

What are the types of industrial water filters?

There are many types of industrial water filters, each type has its own specific working principles and applicable scenarios. Here are some common industrial water filter types:

First, a mesh filter is the simplest and most common type of industrial water filter. It uses the microporous structure of the screen to intercept solid particles in the water, and is often used to remove large impurities and suspended solids in the water.

Secondly, the sedimentation filter uses gravity to settle suspended solids in the water to the bottom, and then removes impurities from the water through the upper filter medium. This filter is suitable for treating wastewater containing large amounts of suspended solids.

In addition, the particle filter separates particles, microorganisms, etc. from the water through multi-layer filter media. Filter media with different particle sizes and materials can remove impurities of different sizes and properties, and are therefore suitable for treating various water quality situations.

In addition, activated carbon adsorption filter is a type of filter commonly used to remove organic matter, odor and color from water. Activated carbon has strong adsorption capacity and can effectively remove organic substances and odors in water, making the water cleaner and purer.

To sum up, there are many types of industrial water filters, and each type has its specific application scenarios, advantages and disadvantages. Choosing a suitable industrial water filter requires considering water quality characteristics, purification requirements and specific production needs to ensure the expected purification effect.

What are the application fields of industrial water filters?

Industrial water filters are widely used in many different fields, and their importance is self-evident. Let us take a look at the applications of industrial water filters in various fields.

1. Manufacturing: In the manufacturing industry, industrial water filters are used to treat cooling water, washing water, and spray paint water during processing. By removing particles and impurities from water, industrial water filters protect equipment and increase production efficiency.

2. Food and Beverage Industry: The food and beverage industry has very strict water quality requirements because water is the main ingredient in many foods and beverages. Industrial water filters are widely used in these industries to purify water sources and ensure product safety and quality.

3. Pharmaceuticals and Biotechnology: In the pharmaceutical and biotechnology fields, water quality is critical to product purity and quality. Industrial water filters are used to purify water sources in pharmaceutical processes to ensure that the final product meets standards.

4. Energy industry: The energy industry also has a large demand for water resources. Industrial water filters are widely used in oil extraction, power production and chemical industry processes to treat water and protect equipment.

What is the importance of industrial water filters in industrial production?

Industrial water filters play a vital role in industrial production. First, they help industrial companies provide high-quality water resources to ensure stable and efficient production processes. Clean water helps reduce equipment wear, extend equipment life, and improve product quality.

Secondly, industrial water filters also play a key role in protecting the environment. By removing contaminants from wastewater, industrial water filters can reduce pollution of water bodies and protect ecosystems and water sources. Many countries and regions have set strict standards for industrial wastewater discharge, and industrial water filters help companies comply with these regulations and avoid fines and lawsuits.

Additionally, industrial water filters are particularly important in specific industries such as food and beverage, pharmaceutical, chemical and electronics manufacturing. These industries have extremely high requirements for water quality, and industrial water filters can ensure that the water in the production process meets relevant standards, thereby ensuring product quality and safety.

How to choose the right industrial water filter?

Choosing the right industrial water filter depends on a variety of factors, including the nature of the water to be treated, treatment capacity, filtration accuracy, and budget. Before choosing, companies need to conduct a detailed analysis of the water to be treated to understand the types and concentrations of pollutants in it.

Secondly, consider the processing power and efficiency of the filter. Different types of filters differ in processing speed and accuracy, and companies need to choose appropriate equipment based on actual needs. For example, a reverse osmosis system can provide high-purity water, but its treatment rate is slower, while a sand filter is suitable for handling large flows of water, but its filtration accuracy is lower.

In addition, maintenance and operating costs are also important factors to consider when choosing an industrial water filter. Some filters require regular replacement of filter media and have higher maintenance costs, while others are relatively economical. Businesses should make decisions based on budget and long-term operating costs.

Finally, companies should choose reputable suppliers to ensure filter quality and after-sales service. Reliable suppliers can provide technical support and training to help companies better manage and maintain industrial water filters.

Industrial water filters play a key role in industrial production, they help improve production efficiency, protect the environment and ensure product quality. When choosing a suitable industrial water filter, companies need to comprehensively consider factors such as the nature of the water to be treated, treatment capacity, maintenance costs and supplier reputation. Through the correct selection and rational use of industrial water filters, companies can achieve better results in industrial production.