High TDS Water Desalination & Purification Systems

High TDS Water Desalination & Purification Systems

Chunke industrial and commercial water treatment equipment are design to remove TDS from your source water. For this one we are using pretreatment, reverse osmosis, ultra-filtration. Electrodeionization systems. UF does not make high effect on TDS but it can be used as filtration before reverse osmosis system.

Seawater TDS is more than 35000ppm, this is really high TDS and need very big high pressure pumps to make adequate pressure for membrane. If water TDS is more than 40,000ppm, we call this one high TDS water, if water is brine, TDS becomes over 100,000ppm. Chunke has solution to reduce TDS for this kind of water.

HIGH TDS WATER DESALINATION & PURIFICATION SYSTEMS

Brine treatment technologies are one of the important sections of industrial and commercial water treatment equipment production. Brine treatment technologies also use RO membrane technology. The use of RO to treat and recover reject from another RO system is becoming more common in industrial and commercial water treatment equipment, particularly in ZLD (zero liquid discharge) applications, it is new technology in water treatment plant. A secondary RO is used to treat the reject from the primary RO to reduce the thermal evaporative requirements of the ZLD system.

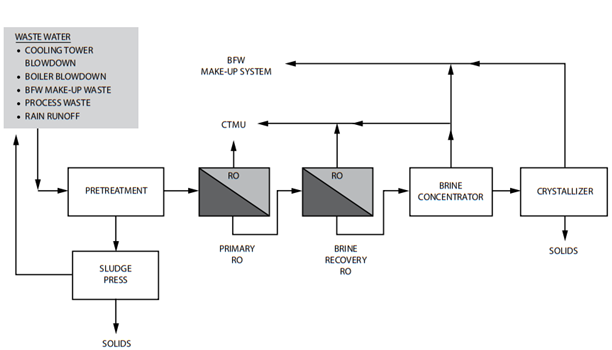

Below Figure shows a ZLD system as new technology in water treatment plant with RO as a primary and secondary treatment for wastewater. As the figure shows, wastewater from a variety of sources, including cooling tower and boiler blow downs, boiler feed water makeup treatment wastes, and process wastes, is sent to the pretreatment system. This pretreatment system typically consists of a cold lime softener, either in traditional form or using micro filtration for industrial and commercial water treatment equipment. If the wastewater is high in organics, additional treatments might include digestion (aerobic and/or anaerobic), dissolved air flotation, and stripping. Waste from the pretreatment system is sent to a sludge press, which, in turn, yields cake solids and another wastewater stream that is recycled to the head-works of the ZLD system. The effluent from the pretreatment system is sent to an RO, the product of which can be sent back to the cooling tower.

Reject from the primary RO is sent to a concentrate or secondary RO. Th e secondary RO is typically a seawater system, capable of operating in the range of 45,000 to 85,000 ppm TDS. Reject from the secondary RO is sent to the thermal system, consisting of a brine concentrator and a crystallizer. The brine concentrator can achieve a concentration of about 300,000 ppm; the crystallizer yields salt solids.

Using the secondary RO reduces the load on the brine concentrator by about 20%. This translates into a corresponding 20% energy savings for a single-effect brine concentrator. Capital cost of the system is also significantly reduced, as the size of the brine concentrator, one of the most expensive pieces of capital equipment in the process, can be smaller. But frankly speaking this kind of ZLD system costs are very high, but we are everyday studying on new technology in water treatment plant and trying to reduce investment cost.

Chunke as Industrial and commercial water treatment equipment company, try to give you best solution by using new technology in water treatment plant. Brine treatment technologies is kind of heavy-duty industry, so it needs experience and knowledge. Brine treatment technologies can be used also in salt production.

Industrial and commercial water treatment equipment concentrated water can be brine. In industry, some examples of brine waste created as a byproduct of industry include:

· Cooling tower and boiler effluent

· Reverse osmosis (RO) and ion exchange waste/reject streams

· Produced water from extracting oil and natural gas

· Chloral-alkali and chemical plant waste

· Acid rock and mine drainage

· Food preservation and manufacturing waste streams

· Desalination waste from potable water creation

· Irrigation runoff

These industries need brine treatment technologies and they always looking for new technology in water treatment plant.